Magnetic drive pump

Magpro magnetic drive centrifugal pumps

- Few types - great flexibility

- Excellent chemical resistance

- Achieve the higher torque by using stronger drive magnets and internal magnet segments

- Standard suitable for max. density 2000 kg/m³) and just change the motor power

- Fast and reliable deliveries

- Easy installation

- No leakage

- Long operational life

- Easy to maintain

- Injection moulded pump head

- High purity (99,7% pure) ceramic pump shaft and thrust rings

- Pump bearing made of Rulon W for wide area of chemicals and applications

- Corrosion resistant PP injection moulded bracket

- Turbine impeller standard made of PVDF for max. stability

Product range

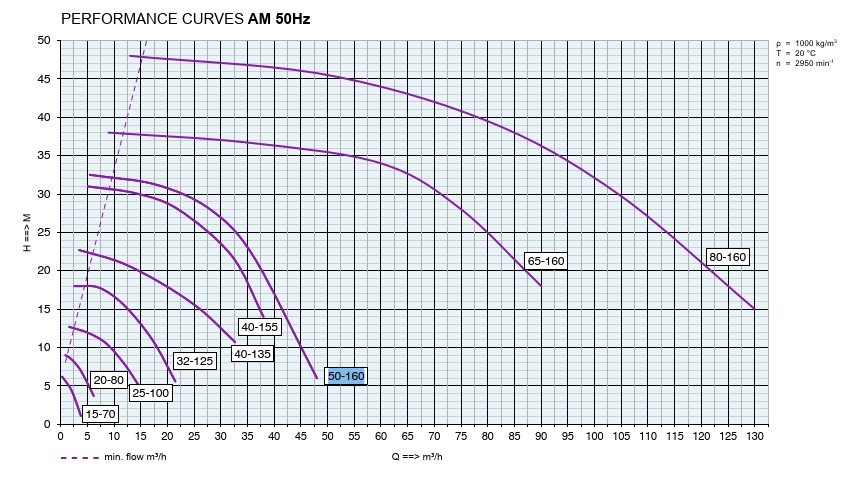

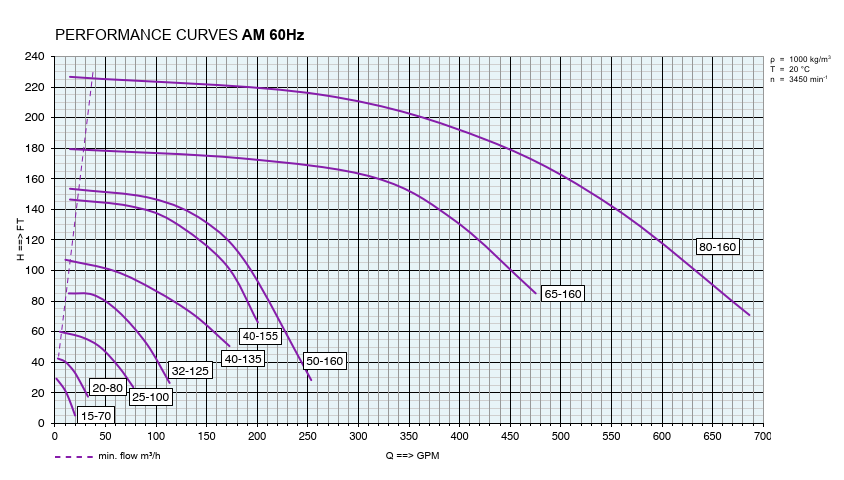

| AM Magpro series |

|

| AM pumps are normal priming end-suction centrifugal pump with magnetic drive. • up to flow rates of 130 m³/h • up to 48 m delivery head |

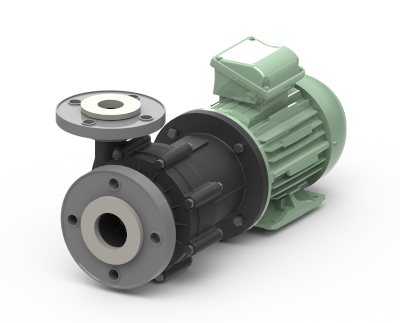

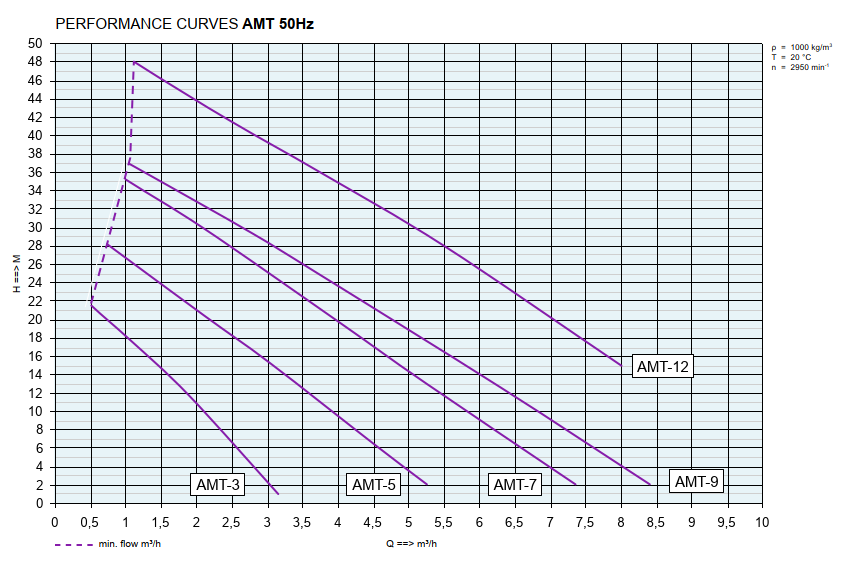

| AMT Magpro turbine series |

|

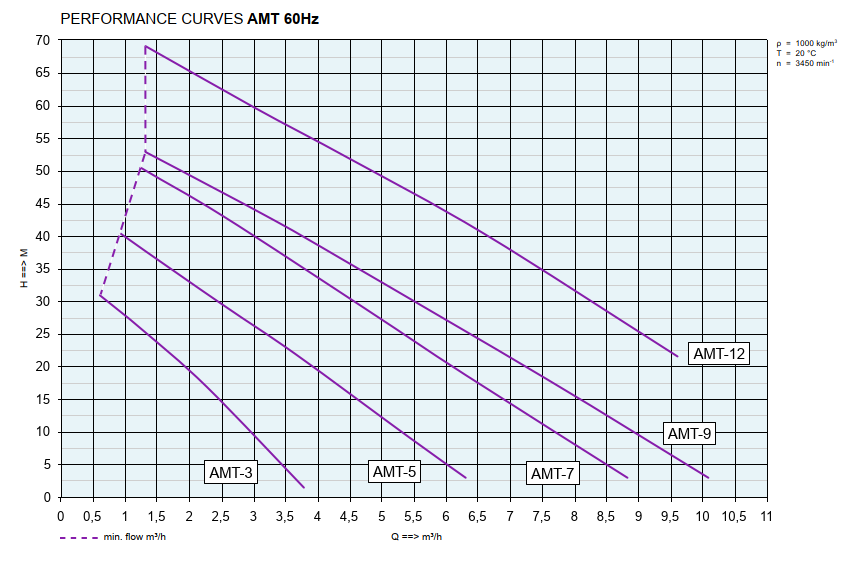

| AMT pumps are equipped with a turbine shaped high efficiency impeller in PVDF. Opposed to the AM end-suction centrifugal pump, the suction is located radially like the discharge. Thanks to the construction, suction and discharge port may be inversed. It is possible to rotate the pumphead by 45º in order to suit your piping. This type of pump is particularly suited for low flow – high head requirements. • up to flow rates of 8,5 m³/h • up to 46 m delivery head |

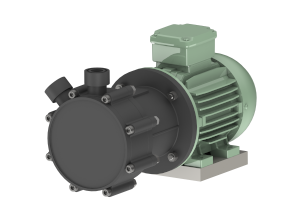

| AMT Self-priming (ZA) series |

|

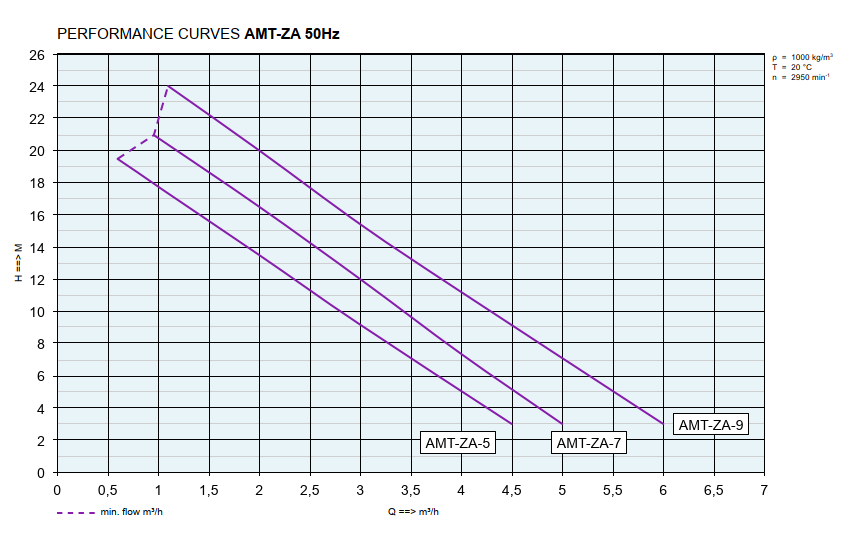

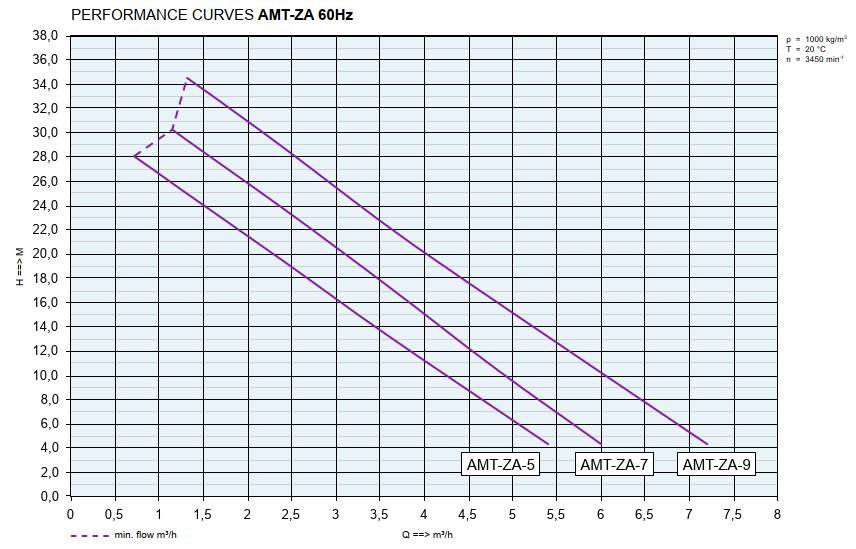

| AMT pumps with build in priming unit, are able to pump liquids containing gas up to 20% and their self-priming ability prevents vapor locking and avoids the necessity of permanent flooded pipe-works. These models have machined pump heads. • up to flow rates of 8,5 m³/h • up to 33 m delivery head • up to 5 m suction lift |

Download

![]() 2.0 Leaflet ARBO Magnetic drive pumps EN.pdf

2.0 Leaflet ARBO Magnetic drive pumps EN.pdf

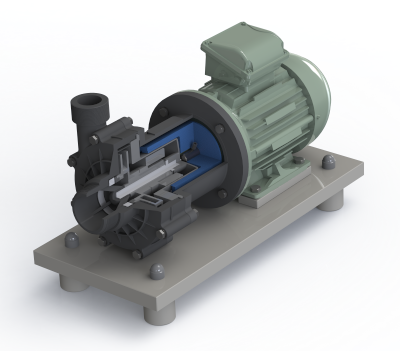

Magnetic drive |

| Magnetic drive centrifugal pumps are Seal-less. The driving torque is transmitted by a permanent magnetic coupling to an internal magnet that moves the impeller. They are energy efficient and can circulate a variety of fluids. |

No leakage |

| Magnetic drive pumps (like most sealless pumps) have a higher initial costs than comparable centrifugal pumps, but offer reduced operating costs thanks to the lack of seal replacement, cleanup, waste, and downtime. They are particularly useful for transporting hazardous or expensive chemicals because there is no mechanical seal, eliminating the possibility of leakage. |

Construction |

| Many years of experience resulted in this latest design in pump technology. The fluid section is sealed by solid plastic parts and the highest grade of anti-corrosion materials are used in the manufacture of the spindle, bearing and mouth ring, which combined with leak-free seal-less structures, ensure the safe and durable transfer of strong acids and strong alkaline liquids. For most of the applications, Polypropylene (PP) is sufficient. If concentrated chemicals must be pumped and/or at higher temperatures, the medium contact materials consists of PVDF. The plastic parts are reinforced with fibres. As a result, the pump is stronger despite the fact that less material is used, and retains its physical characteristics in the case of possible increases in temperature and/or pressure.In this way, the chance off leaking gaskets is minimized. |

Impeller |

| AM pumps are equipped with a closed impeller (except the smallest type that has an open impeller), with optimum efficiency. It is fixed onto the shaft independent from the direction of rotation. For all transport or circulation duties of pure chemicals or other corrosive liquids. |

Standard materials of construction |

|

Solid particles |

| The AMT pumps are equipped with a turbine impeller. Thanks to the tight tolerances between the pump housing and impeller, the pump achieves a relatively high pressure. However, this feature makes the pump non suitable for pumping particles. If your liquid contains particles, a strainer should be installed in the suction line to protect the pump! In order to save on costs on repair jobs, these pumps are provided with wear plates in the pump housing. |

Motors |

| All motors are according NEN-EN-IEC 10072-1 DIN 42673 NEN3321 standard, 2- or 4-pole for 230/400 V or 400/690 V / 50 or 60 Hz, IP55, ISO class F. Other protection classes against dust and or humidity on request. |

Atex |

| All RVS magnetic drive pumps can be supplied with zone II, Atex II 2G e II T3 certification. |

|

Paint system |

| These pumps are often used in corrosive environments. Therefore all metallic parts are coated according NEN-EN-ISO 12944-5 category C3 suitable for outdoor installation. Other painting categories and colors on request. |

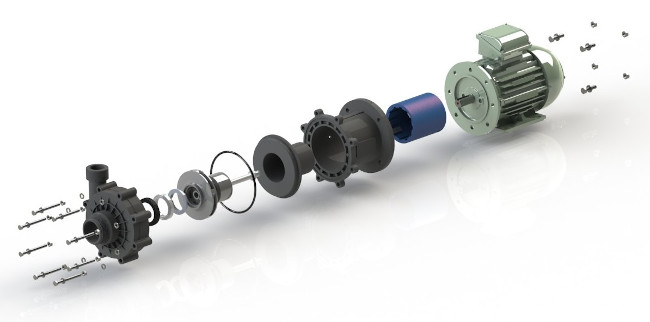

Maintenance |

| All pumps are supplied with threaded connections or flanges according DIN standard. During inspection and/or reparation the process connections (suction and discharge) can remain in place. The number of parts has been reduced to a minimum and therefore the pump has only very few wear parts. At the same time servicing can be carried out efficiently so that down time and production losses are reduced to a minimum. |

Options |

|

|

Performance curves Magpro AM

|

|

Performance curves AMT

|

|

Performance curves Magpro AMT - ZA

|

|